June 16, 2024 by Heather

How To Choose The Right Steel For Your Project –

Part 1: Understanding the Basics of Knife-Making Steel

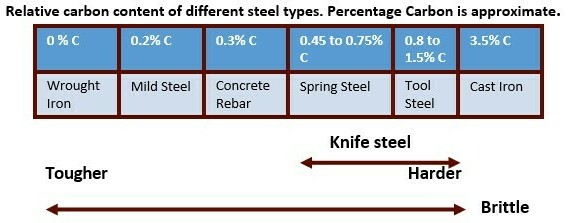

An Overview of steel properties: toughness vs. hardness

As an Amazon Associate I earn from qualifying purchases.

List of Knife-Related Suppliers in South Africa.

Choosing the Right Steel for Your Knife

When deciding on the steel for your knife, you need to consider its intended use. Here are a few scenarios:

- Toughness Requirement: If your knife will be used for tasks that involve a lot of impact, such as chopping wood or butchering meat, you will need a steel that offers high toughness. Spring steel, known for its flexibility and ability to withstand impact forces, is an excellent choice for such applications. Carbon steels like 5160 and 1070 are popular options.

- Extreme Hardness Requirement: For tasks requiring a blade to maintain a razor-sharp edge over a long period, such as slicing and detailed cutting, a steel with extreme hardness and wear resistance is desirable. Tool steels, like W2 provide the necessary hardness and edge retention, making them ideal for these purposes.

- All-Around Performance: If you need a versatile knife that performs well in a variety of tasks, choosing a steel that offers a good balance between toughness and hardness is key. Steels like 1084 and 5160 are popular “go-to” steels.

Heat Treatment: The Key to Steel Performance

The properties of steel can be significantly altered through heat treatment processes such as hardening and tempering. These processes manipulate the microstructure of the steel to enhance its performance characteristics.

- Hardening: This process involves heating the steel to a temperature referred to as “critical temperature” and then rapidly cooling it, usually in oil.

- Tempering: After hardening, the steel is often too brittle for practical use. Tempering involves reheating the steel to a lower temperature and then allowing it to cool. This process is repeated. This reduces brittleness and improves toughness without significantly compromising hardness.

The Dilemma of Steel Selection

Choosing the right steel for a knife involves balancing various trade-offs. Here are some key points to consider:

- Spring Steel: Ideal for blades that need flexibility and impact resistance. However, without proper tempering, spring steel can be too brittle in its fully hardened state.

- Tool Steel: Offers exceptional hardness and wear resistance, but may lack the flexibility required for certain tasks. Proper tempering is crucial to balance hardness with toughness.

- Carbon Content: Higher carbon content generally increases hardness but can also increase brittleness if not properly tempered. Selecting steel with appropriate carbon content and ensuring correct heat treatment is vital.

Recommendations for Knife Makers

Given the complexity of steel selection, it’s often best to start with a few popular steels from different families and master their use. Here are a couple of suggestions:

- 5160 Spring Steel: Known for its excellent toughness and flexibility, making it a great choice for heavy-duty knives.

- W2 Tool Steel: Offers superior hardness and edge retention, suitable for fine cutting tasks and knives that require long-lasting sharpness.

Remember the adage: “I would rather use an inferior steel with superior heat treatment than a superior steel with an inferior heat treatment.” Proper heat treatment is the key to unlocking the potential of any steel.

Conclusion

Understanding the properties of steel and the impact of heat treatment is essential for selecting the right steel for your knife. Whether you need toughness, extreme hardness, or a versatile all-around performer, the correct choice and treatment of steel will ensure your knife meets your performance expectations. You can create knives that excel in their intended applications by mastering working with a few selected steels and perfecting your heat treatment process.

Part 2: Assessing Fabrication and Heat Treatment Methods

When it comes to working with steel, understanding the various fabrication and heat treatment methods is crucial for achieving the desired results. Whether you’re a seasoned blacksmith, a budding knife-maker, or a DIY enthusiast, knowing the nuances of these techniques will help you make informed decisions about steel selection and processing. In this post, we’ll compare forging and stock removal, explore different hardening methods, discuss the decision-making process for DIY versus professional heat treatment, and consider the availability of tools when choosing steel.

Comparing Forging to Stock Removal Techniques and Their Impact on Steel Selection

Forging: Forging involves heating steel to a high temperature and then shaping it using hammers and other tools. This process aligns the grain structure of the steel, improving its overall strength and toughness. Forging is ideal for creating strong, durable items that need to withstand significant stress and impact.

Impact on Steel Selection:

- High-Carbon Steels: Steels like 1095 or 5160 are preferred for forging due to their high carbon content, which enhances their ability to harden and retain sharp edges. https://amzn.to/45XoBMn

- Alloy Steels: Steels with added elements like chromium, vanadium, or molybdenum (e.g., O1 or W2) offer improved wear resistance and toughness, making them suitable for high-performance tools and blades.

- Medium to High Carbon steels can be differentially heat treated, creating a hard cutting edge with a tough, springy spine. This makes for a brilliant, high-performance blade that can withstand “abuse.”

Stock Removal: Stock removal is a method where the desired shape is achieved by grinding away excess material from a steel blank. This technique doesn’t alter the internal structure of the steel as forging does, making it simpler and less labour-intensive. Slightly less equipment is required for this method. Stainless steel cannot be differentially heat-treated like carbon steel.

Impact on Steel Selection:

- Stainless Steels: Steels like 440C or S30V are popular for stock removal because they maintain their properties without needing the grain refinement that forging provides. Forging stainless steel has no benefit. https://amzn.to/4cxWYfm

- Tool Steels: D2 or O1 tool steels are favoured for their excellent wear resistance and ability to hold a sharp edge, making them ideal for precision cutting tools.

Different Hardening Methods and How They Influence Steel Choice

Hardening and Tempering: This traditional method involves heating the steel to the correct temperature for that type of steel (austenitizing) and then rapidly cooling it (quenching) in oil or air, followed by reheating to a lower temperature (tempering) to reduce brittleness.

Steel Choice:

- Oil-Quenched Steels: Steels like 1084 and 5160 are well-suited for oil quenching, offering a good balance of hardness and toughness. Quenching oil can be bought here https://amzn.to/3VRLJHH

- Water-Quenched Steels: such as W2 are only quenched in water in industry when large machine parts are made. Small delicate knives forged from his steel should be quenched in oil.

Differential Hardening: This technique involves hardening only specific parts of the blade, leaving other areas softer and more ductile. This method is often used for blades to create a hard edge and a tough spine.

Steel Choice:

- Clay-Coated Steels: High-carbon steels such as W2 or 1095 are commonly used, with clay applied to areas meant to remain softer, creating a differential hardness along the blade and results in a beautiful “Hamon” or hardening line which is visible to the naked eye.

The Decision-Making Process for DIY Heat Treatment Versus Professional Services

DIY Heat Treatment: Choosing to perform heat treatment yourself can be rewarding and cost-effective, but it requires knowledge, skill, and proper equipment.

Considerations:

- Equipment: A forge, heat-treating oven, quenching tanks, and tempering ovens are essential.

- Skill Level: Understanding the critical temperatures and quenching techniques is crucial to avoid damaging the steel.

- Cost: While initial setup can be expensive, DIY heat treatment can save money in the long run. Because each knife is heat treated individually, the process is fully within your control and done correctly.

Professional Heat Treatment: Opting for professional services does not always ensure precision and consistency, which is particularly important for critical applications. This problem occurs when professional heat treaters add your knife to a batch of other components, often resulting in the heat treatment being done at the incorrect temperatures.

Availability of Tools: Choosing Steel Based on Whether You’re Using Hand Tools or a Belt Grinder

Hand Tools: When working with hand tools, choosing steels that are easy to work with and don’t require excessive force or advanced techniques is important. Ensuring that the steel has been fully annealed is paramount.

Steel Choice:

High-Carbon Steels: 1084 or 5160 steels offer a balance of ease of working and good hardening potential.

Belt Grinder: A belt grinder allows for more aggressive material removal and can handle harder steels, making it ideal for more advanced projects. Belt grinders can be purchased here https://amzn.to/3VUOloj

Steel Choice:

- Tool Steels: O1, W2, and similar steels are suitable for use with a belt grinder, providing excellent edge retention and wear resistance.

- Stainless Steels: Steels like 440C or S30V can be efficiently shaped and finished with a belt grinder, offering corrosion resistance and hardness. If they are bought in the fully annealed state, they can be worked by draw-filing and pure hand work.

Conclusion

Selecting the right fabrication and heat treatment methods is essential for achieving the desired properties in your knifemaking projects. Whether you’re forging or using stock removal, choosing appropriate hardening techniques, and deciding between DIY and professional heat treatment, all these factors significantly influence your steel selection. Additionally, the availability of tools, whether hand tools or a belt grinder, will guide you in choosing steels that match your capabilities and project requirements. By understanding these methods and their impacts, you can make informed decisions and ensure the success of your metalworking endeavours.

Leave a Reply