July 10, 2024 by Heather

The Small Things that Make a Big Difference

Little tools that make a big difference in your bladesmithing

At each workbench, we have some basic hand tools https://amzn.to/460LTBl that every knifemaker will need. A scribe, a pair of dividers, a small steel ruler, a small engineer’s hammer, a tiny piece of railway track to punch onto, a centerpunch, a piece of leather to protect your blade in your swivel (knifemakers vice) https://amzn.to/3SpyahV or machinist’s vice https://amzn.to/3RZj8yY and a scribe. You can add more depending on your project. Try to keep them all together and at easy reach to make your life easier.

As an Amazon Associate I earn from qualifying purchases.

List of Knife-Related Suppliers in South Africa.

You need to accurately lay out your pin holes and centre punch them. Your lighting amzn.to/4cWb6Pk should be excellent over your workbench. The bench should be at a comfortable height for you to work at while standing up. Have a piece of carpet on your bench to lay your blades on so that they don’t get scratched. A good big piece of rubber matting is useful to stand on, not only for your comfort but to save the blades that you will inevitably drop from either breaking or ruining your floor!

Plan every part of your knife and leave space on your workbench to draw. A pencil and eraser will be used constantly. Keep all of your drawings in a file for future reference. Templates in tin of blade and handle shapes should also be kept as you can “mix and match” when designing a new knife.

Look after your files by not throwing them all together in a drawer. With needle files https://amzn.to/3W2z2tA add a simple handle to save your delicate knifemaker’s hands from becoming punctured! Your larger files https://amzn.to/4cCimQM should always have a handle. Buy the best quality files you can afford, as the cheap ones will often not last long. Clean your files with a file card to keep them sharp.

Your sand/waterpaper should be kept in marked, closed drawers. Stray pieces of hard grit on the paper will ruin your beautiful polish. When you cut strips off a certain grit of paper, remember to write the grit size on the back of it and return it to the correct drawer. Use an old pair of scissors to cut the paper or one of your reject knives as nothing dulls edges like sandpaper!

Polishing sticks and stones should be kept close by but not out of the way when picking up grit from different grit sandpapers https://amzn.to/460LTBl. If you are polishing hollow ground blades have matching radius sanding blocks for each of your belt grinder wheel sizes.

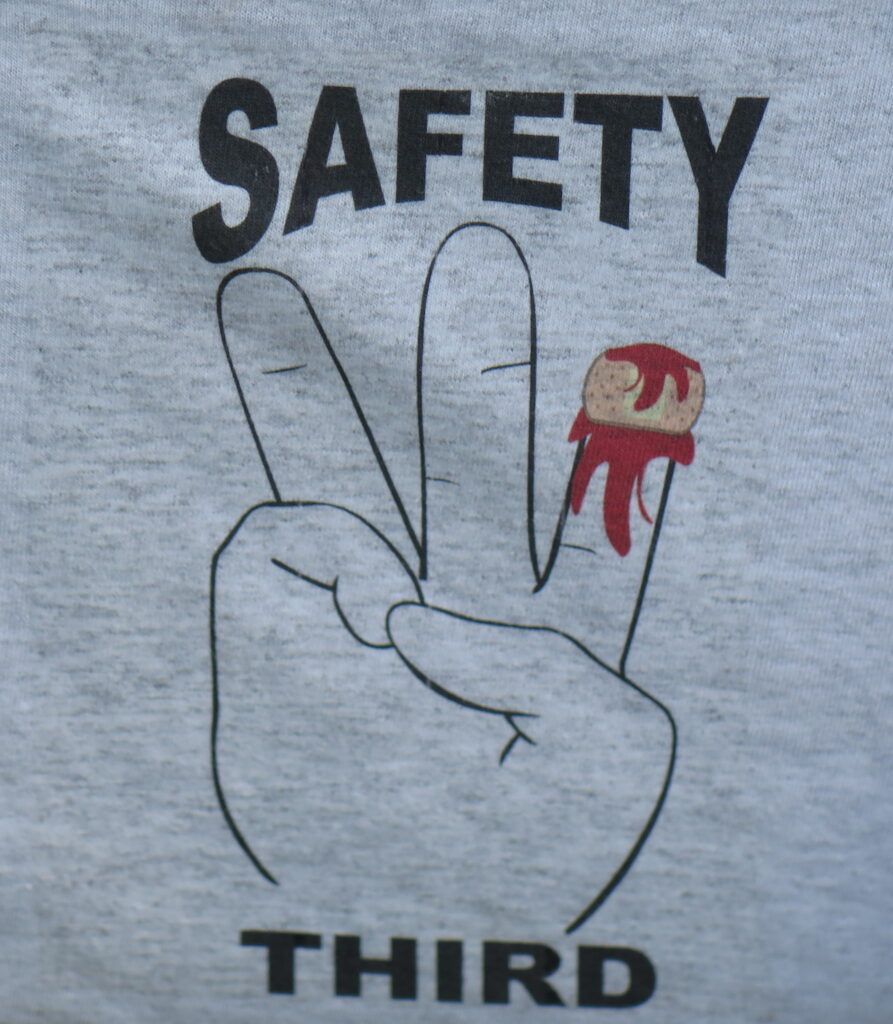

Polish safely on a polishing blocks that prevents you from slicing your fingers or removing your own appendix! Safety first! Luckily we have had very few accidents in our workshop. Most of them have been cuts at the polishing stage, where the blade was not held safely.

Try to get into the habit of keeping your workbench tidy with each tool in its own place. Good craftsmen take great pride not only in their work but also in their tools.

Leave a Reply